Page written by Sam Stites ’12

=================

Sputter Coating Samples

=================

The following are excerpts from the Lab Notebook of Sam Stites, which can be found in Sander’s Physics at Vassar College.

Sputter Coater Operation:

Under the assumption that the sputter coater has been reset and is filled to ~600Torr with Nitrogen

-Open up sputter coater chamber in a star pattern. There are four bolts so thinking about this on a compass rose would mean that this would look something like “North,” “South,” “East,” “West.”

-When taking off the chamber door, sometimes it is easier to push the door off by sliding it in a direction. Once the seal has broken the door will fall off easily.

-Using gloves, reach in and take out the sample’s plate – don’t worry too much about hitting the chamber’s sides when you reach in. Lock the sample onto the plate with the hex key and put the sample back in. One of the screws will sit inside the PVC pipe which forms the platform holder and the other will sit outside of this tubing. it seems a little awkward but it is stable.

-If the Coater has not been used in a while, take the rubber o-ring off of the door and rub a decent amount of machine lubricant onto the o-ring track. check to make sure that the o-ring does not have any foreign objects in it – hair, pieces of plastic or anything which would put the seal in jeapordy. If you want to be extra precautious you can add a thin coat of machine lube above the o-ring for a garunteed seal.

-With the o-ring in place on it’s track- fit all the bolts onto the door and put the door in place so that the o-ring only moves minimally when the door is resealed. put the nuts on each bolt and tighten to finger tightness first. It is more important to have an even pressure on all the bolts than to have the bolts fastened tightly and if you tighten a bolt too much on one side, the opposite bolt will loosen. After the bolts have been initially tightened, use two wrenchs to tighten them to about an eigth of a turn.

-recheck all the bolts by a simple finger turn on each. if the bolts are loose, tighten with wrenchs and repeat the check.

-Press Start/Stop on the Turbo-Vacuum. Flip the switch on the vacuum itself.

-Wait until the Convection Gauge dail goes to/past 0 mTorr.

-As you wait, you can wash your hands if you happen to touch any machine lube. To remove the machine lube, first rinse your hands with oil (I used vegetable oil from my kitchen) and then scub with handsoap. After this, wash with water and soap again.

-Once the Convection gauge passes 0 mTorr, turn on the power to the ion gauge and flip the switch for “filament” and “auto” (auto should be on).

-Wait for the Ion Gauge to reach any single digit at a magnatude of x10^(-6). At this point it is assumed to be a good enough vacuum to continue. This waiting process takes about 1.5 hours.

-At this point the steel cables are still filled with Nitrogen from before. Open the flow from the steel cables via black knob. Wait for the ion gauge to return to a x10^(-6) reading.

-Flip switch for argon to flow through steel cables.

-turn the fine adjust dial to allow the Convection Gauge to allow ~2.5mTorr to flow from the tank.

-turn on the water cooler.

-doublecheck that the water cooler is on.

-sometimes water doesnt flow, in this case open up the case and add more water to the tank.

-Go to the power for the plasma gun ( MDX-IK ).

-Flip the switch at the back of the machine

-turn on the power button.

-turn on the output button.

-ramp up the voltage to 400V.

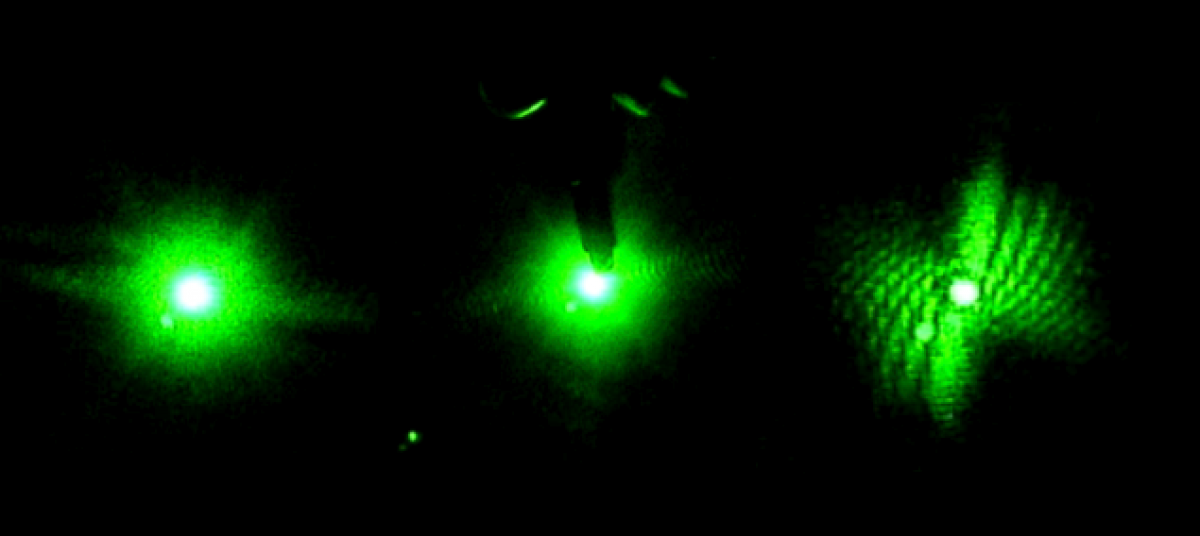

-As the plasma gets rampped up to 400V, it will make a purple hue in the window of the door. At 200V, this hue will flicker – at this point, the ions are not sputtering the sample and you should sit at this voltage to wait for the flickering to stop. Once finished, use the “ramp” dial to ramp the voltage up to 400V.

-If you are running multiple samples in the same sitting – or even in sequence – you can simply leave the rampped up voltage at the same place and turn off the machine. The next time you start up and initiate output, after the machine fluxuates between voltages and initiates the flickering it will start an output of the same voltage as your last run.

-once the machine is outputting 400V -or the desired voltage- start the timer.

-turn off the machine in the reverse order with which you turned it on (output off, power off, back switch off).

-turn off the water flow.

-turn the fine adjust knob to close off argon flow.

-switch off argon flow.

-close the opening to the steel cables

-Make sure that the Nitrogen tank is open by making sure the knob immediately above the tank is turned counter-clockwise. If the tank is closed, there will be resistence to the ccw turn – you only need to turn the knob past this resistance.

-Flip the switch for Nitrogen to flow from the tank.

-open the fine adjust knob.

-turn off the vacuum both on the Turbo-Vacuum Interface and on the vacuum itself.

-open up the flow from the steel cables.

-wait for the Convection Gauge to read 600 Torr.

-To allow for a speedier fill, fully open the fine adjust knob to allow free flow of gas into the chamber. At 400 Torr, turn the fine adjust down halfway and at 500 Torr turn off the Nitrogen Tank flow from directly on the tank.

-At 600 Torr, I have found that the meter seems to ‘skip’ 600 Torr and jumps to 650 or 700 Torr. This should be fine.

-Open up the chamber as before and take out your sample.

-When you are finished using the machine, run the vacuum once again to remove air from the sputter coater, then reinitialize the sequence to fill the coater with Nitrogen. DO NOT leave the sputterer unattended filled with anything but nitrogen gas.

=================

Samples:

=================

The following samples are from the final 12 that are to be analyzed under a LIBS specturm. From prior work done over the summer by Karl Spuhler (see lab notebook) we know that the gun coats samples at a rate of ~2.3nm/s and the estimates of each aluminum ion coating is determined by a simple algebra derivation using his work. The error term for timing was using several time trials for my individual reaction time at humanbenchmark.com (http://bit.ly/PRUov).

Sample 1:

Voltage:

398 +- (0 V + machine’s accuracy)

Pressure in Chamber:

2.8 +- 0.125 mTorr

Time:

40.83 +- 0.21 s

Layer Thickness:

93.909 +- 0.483 nm

Sample 2:

Voltage:

398 +- (1 V + machine’s accuracy)

Pressure in Chamber:

2.5 +- 0.125 mTorr

Time:

60.10 +- 0.21 s

Layer Thickness:

138.23 +- 0.483 nm

Sample 3:

Voltage:

397 +- (1 V + machine’s accuracy)

Pressure in Chamber:

2.4 +- 0.125 mTorr

Time:

1:20.18 +- 0.21 s

Layer Thickness:

184.414 +- 0.483 nm

Sample 4:

Voltage:

398 +- (2 V + machine’s accuracy)

Pressure in Chamber:

2.5 +- 0.125 mTorr

Time:

1:40.09 +- 0.21 s

Layer Thickness:

230.207 +- 0.483 nm

Sample 5:

Voltage:

398 +- (0 V + machine’s accuracy)

Pressure in Chamber:

2.5 +- 0.125 mTorr

Time:

2:00.11 +- 0.21 s

Layer Thickness:

276.253 +- 0.483 nm

Sample 6:

Voltage:

398 +- (1 V + machine’s accuracy)

Pressure in Chamber:

2.8 +- 0.125 mTorr

Time:

2:19.92 +- 0.21 s

Layer Thickness:

321.816 +- 0.483 nm

Note: Sample 5 was giving slight signs of over saturation and Sample 6 showed heavy signs of over saturation. Since this meant that the coating was not being distributed evenly, I decided to start to work backwards to fill out the sample distribution with 23nm (10s) increments as opposed to 46nm (20s) increments.

Sample 7:

Voltage:

398 +- (0 V + machine’s accuracy)

Pressure in Chamber:

2.5 +- 0.125 mTorr

Time:

2:10.10 +- 0.21 s

Layer Thickness:

299.23 +- 0.483 nm

Sample 8:

Voltage:

398 +- (0 V + machine’s accuracy)

Pressure in Chamber:

2.8 +- 0.125 mTorr

Time:

1:50.14 +- 0.21 s

Layer Thickness:

253.184 +- 0.483 nm

Sample 9:

Voltage:

397 +- (2 V + machine’s accuracy)

Pressure in Chamber:

2.8 +- 0.125 mTorr

Time:

1:30.08 +- 0.21 s

Layer Thickness:

207.184 +- 0.483 nm

Sample 10:

Voltage:

398 +- (1 V + machine’s accuracy)

Pressure in Chamber:

2.4 +- 0.125 mTorr

Time:

1:09.96 +- 0.21 s

Layer Thickness:

160.908 +- 0.483 nm

Sample 11:

Voltage:

398 +- (1 V + machine’s accuracy)

Pressure in Chamber:

2.4 +- 0.125 mTorr

Time:

50.25 +- 0.21 s

Layer Thickness:

115.575 +- 0.483 nm

Sample 12:

Voltage:

398 +- (2 V + machine’s accuracy)

Pressure in Chamber:

2.5 +- 0.125 mTorr

Time:

30.22 +- 0.21 s

Layer Thickness:

69.506 +- 0.483 nm